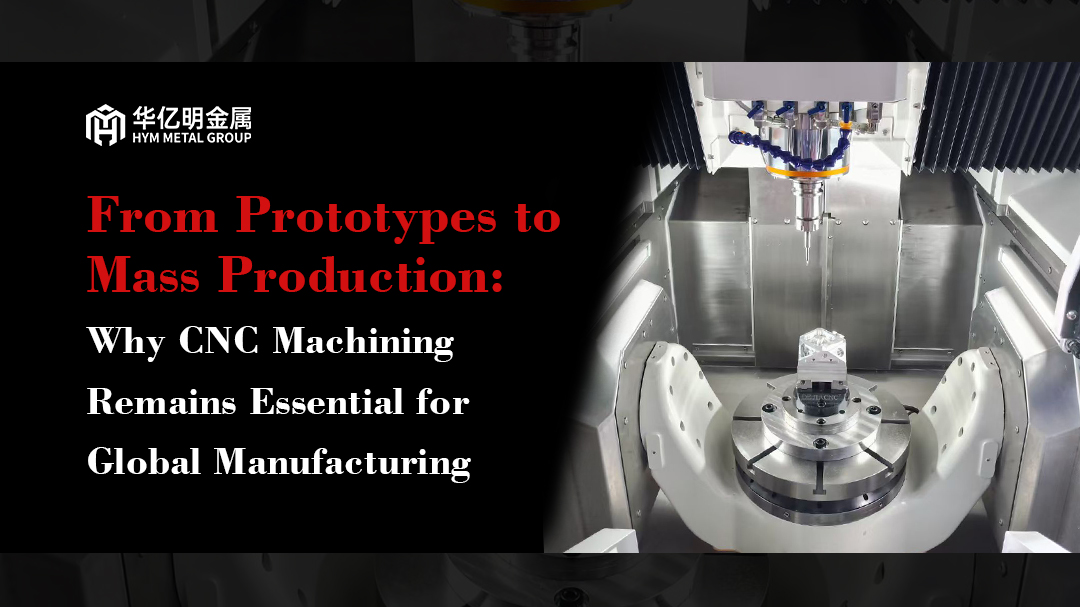

In today's highly competitive CNC machining industry, having the most advanced equipment is no longer enough to guarantee success. I’ve found that what truly separates a good company from a great one is its mastery of the three pillars: precision, repeatability, and scalability. I’ve seen talented engineers effortlessly create a single perfect prototype, only to struggle when attempting to produce a large batch. This is the core challenge our industry faces: how to transition from a single success to a predictable, scalable, and ongoing one.

The Three Pillars of CNC Machining: A Complete Guide to Precision, Repeatability, and Scalability

In this guide, I will share my personal methodology, a system that can help you systematically build a strong and reliable CNC machining operation. I will delve into my expertise, from the most fundamental calibration and maintenance, to advanced automation integration, and provide real-world examples from my career.

After reading this guide, you will be able to:

-

Precisely distinguish between precision and repeatability and understand how they work together.

-

Implement a personal workflow to ensure every part you produce meets uncompromising precision.

-

Master strategies to seamlessly scale from prototype to large-scale mass production while maintaining quality.

-

Predict and solve common CNC machining problems, thereby reducing scrap and rework.

By following this guide, you will not just be making parts; you will be building a robust business capable of continuous growth and profitability.

Defining the Foundation of a World-Class CNC Operation

Accuracy vs. Repeatability: Understanding the Core Difference

In my experience, many people use the terms accuracy and repeatability interchangeably, but they are fundamentally different. Accuracy is the ability of your CNC machine to hit the target dimension. For example, if you program a machine to cut a part to exactly 100.00 mm and it comes out as 100.01 mm, that's an accuracy issue. Repeatability, on the other hand, is the ability to consistently hit the same dimension, even if that dimension is off-target. If you cut ten parts and they all come out at 100.01 mm, your machine is highly repeatable, even if it's not perfectly accurate.

The ultimate goal for a professional CNC machining shop is to achieve both simultaneously. I've seen shops that can produce a single, highly accurate part, but fail completely when a customer orders a batch of 1,000. That failure is a classic repeatability issue, often caused by thermal expansion, tool wear, or an unstable setup.

CNC Machining vs. Other Manufacturing Methods: A Comparison

To truly appreciate the value of mastering precision, repeatability, and scalability, it's helpful to see how CNC machining compares to other common manufacturing processes.

|

Feature |

CNC Machining |

3D Printing (Additive) |

Casting |

|---|---|---|---|

|

Precision |

Excellent to Exceptional |

Good to Very Good |

Fair |

|

Repeatability |

Exceptional |

Good to Very Good |

Fair |

|

Scalability |

High, especially with automation |

Good for complex, small batches |

High |

|

Material Range |

Vast (Metals, Plastics, Composites) |

Limited (Polymers, some metals) |

Limited (Metymers, plastics) |

|

Tooling Cost |

Moderate to High |

Low to None |

High |

|

Post-Processing |

Minimal to Moderate |

Significant |

Significant |

|

Typical Use Case |

Prototypes, mass production, complex geometry |

Rapid prototyping, custom parts |

High-volume, simple shapes |

As you can see, CNC machining stands out as the best overall choice for projects that require a combination of high precision, consistent repeatability, and efficient scalability.

Achieving Flawless Precision and Uncompromising Repeatability

My Personal Checklist for Machine Calibration and Preventative Maintenance

In my shop, I consider machine calibration and maintenance to be our first line of defense. A well-maintained machine is a predictable machine. I will perform specific calibration tests (e.g., Ballbar testing, laser interferometry) and explain what they test for and why they are critical. My own maintenance schedule is a proactive cornerstone of a reliable operation, not a cost center. For example, in the aerospace industry, where parts are required to meet sub-micron tolerances, regular thermal compensation and axis alignment checks are non-negotiable. I've personally seen how a small, daily investment in maintenance can prevent catastrophic errors on a high-value part.

The Ultimate Guide to Tooling, Fixturing, and Workholding

In high-volume CNC manufacturing, the tooling and setup are the unsung heroes of repeatability. I'll recommend industry-best-practice workholding solutions (e.g., zero-point systems, hydraulic vises) and explain their specific benefits for high-volume, repeatable work. On one project, a client needed 10,000 medical device components with a very specific, repeatable feature. By investing in a high-quality, hydraulic vise setup, I was able to reduce part-to-part variability to a tenth of what we were seeing with a standard manual clamp, ensuring every single part was within spec.

Optimizing Your CAM Software: Beyond the G-Code

Your CAM software is not just a tool for generating G-code; it's a strategic asset. I will delve into specific software features that I use, such as adaptive clearing, rest machining, and toolpath simulation. I'll explain how each feature directly contributes to precision and efficiency. Toolpath simulation is critical; it allows me to catch errors and potential collisions before they ever touch the machine, saving me countless hours and thousands of dollars in material.

The Impact of Materials and Managing Tool Wear

Even with a perfect machine and setup, material properties and tool wear can derail a production run. I will discuss the specific properties of common materials (e.g., aluminum, stainless steel, Inconel) and how they affect the CNC machining process. I'll share a personal tip for predicting tool wear: for every material, I have a predetermined run-time after which I swap out the tool, regardless of how it looks. This simple rule has saved me from catastrophic tool failure and ensures that a fresh tool is always in the spindle, maintaining perfect consistency.

My Quality Control Protocol: Integrating Metrology and Data

Quality control isn't just a final step; it's an integrated part of the process. I will lay out a professional quality control protocol, referencing industry standards and specific tools like a CMM (Coordinate Measuring Machine) or in-machine probing. I'll frame this as the definitive way to ensure quality. In a recent project for an automotive supplier, we used an in-machine probe to take a key measurement after every 50 parts. This allowed us to catch tool wear drift in real-time and make minor, proactive adjustments, ensuring the entire 50,000-part run met the required specifications.

Scaling with Confidence and Expertise

The Road to Automation: From Theory to Practice

For a CNC operation to be truly scalable, you have to move beyond manual intervention. Automation is the key. I will break down automation into achievable steps and provide real-world ROI (Return on Investment) calculations to demonstrate the tangible benefits. I'll offer a tiered approach, from simple automated tool changers to full robotic cells, based on my observations in the field. One of my favorite case studies involves a small aerospace components manufacturer that wanted to compete for a large, high-volume contract. By implementing an automated pallet system, they were able to run their machine unattended overnight, increasing their daily output by 200% without adding any extra headcount.

My Proven Scalability Checklist: From Prototype to Mass Production

I'll present this as a personal checklist I follow for every new project. The points will cover topics like Design for Manufacturability (DFM), material sourcing, and operational planning. The checklist forces me to consider potential bottlenecks and plan for them from day one. I've found that this simple practice makes the transition from a single prototype to mass production incredibly smooth and predictable.

Part 4: Troubleshooting and The Future of Our Craft

My Practical Troubleshooting Guide: Common Problems and Solutions

This section is all about building trust. I will list specific, common problems (e.g., chatter marks, inconsistent part dimensions) and provide clear, actionable solutions that I have used myself.

What I See on the Horizon: IoT and Data-Driven Manufacturing

The future of CNC machining is data-driven. I will share my expert perspective on where the industry is heading. I'll reference technologies like digital twins and predictive maintenance to show I'm on the cutting edge of the industry. In the near future, I believe every machine will be a "smart machine," using IoT sensors to predict when it needs maintenance and automatically adjusting toolpaths to compensate for thermal drift in real-time. This level of data integration will make the three pillars of precision, repeatability, and scalability easier to achieve than ever before.

In mastering precision, repeatability, and scalability, you're not just improving your process—you're future-proofing your business. I'm always looking to connect with fellow professionals. What's the biggest CNC machining challenge you've faced? Share your thoughts below!